RFID Chips 101

An engineer’s cheatsheet of RFID chips used for asset tracking and inventory management.

Passive UHF RFID chips compliant with EPCglobal Gen2v2 and ISO 18000-63 standards have found widespread application in various industrial settings, facilitating reliable asset tracking and inventory management systems.

These chips, also known as RAIN RFID, operate in the 860MHz to 960MHz frequency band and come in a variety of configurations with varied features.

Knowing the kind of chip used in an RFID tag, label, or sensor will thus help assure full compatibility within an existing tracking system, as well as maximize data capture accuracy, interoperability with other systems, and overall security.

Who are the major RFID chip manufacturers?

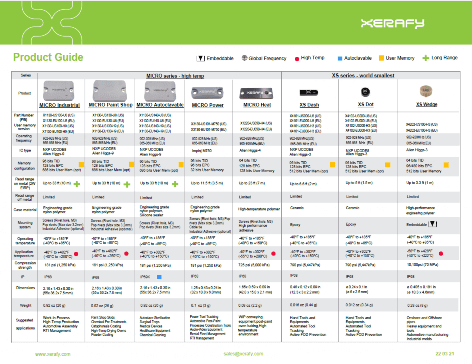

Impinj’s latest additions to its Monza M78x series were announced in November 2022 with the series’ first expanded memory chips, the new M780 and M781 RAIN RFID tag chips.

NXP launched its current UCODE 9 series in 2020, with the fully configurable UCODE 9xm announced in March 2023.

What are the most recent evolutions in RFID chips?

Over the past decade, RFID (Radio Frequency Identification) chips have undergone significant advancements in terms of performance and features:

- Read range and accuracy – These advancements have expanded the adoption of RFID technology across several sectors and use cases, including retail, logistics, healthcare, and manufacturing.

- Data storage capacity – Read Write RFID chips can store more information, enabling the inclusion of additional data, such as product details, manufacturing history, and authentication codes.

- Data transfer rates – This allows for quicker data exchange between the RFID chip and the reader, enabling faster inventory management, supply chain tracking, and asset identification.

- Sensing capabilities – In recent years, RFID chips have started to incorporate sensor capabilities, such as temperature, humidity, and motion sensors. This integration allows for the collection of real-time data and enables more advanced applications, such as cold chain monitoring and asset tracking with environmental monitoring.

- Security and privacy features – RFID chip manufacturers have placed a greater emphasis on security and privacy features. Advanced encryption algorithms and authentication protocols have been implemented to protect data integrity and prevent unauthorized access.

- Cost – The cost of RFID chips has decreased over the past decade thanks to advancements in manufacturing processes and economies of scale. This cost reduction has made RFID technology more accessible to a wider range of industries and applications.

RFID Chips for Asset Tracking

An overview of passive UHF RFID chips compliant with EPCglobal Gen2v2 and ISO 18000-63

| RFID CHIP (click for datasheet) | Examples of RFID Tags | Key Features | EPC MEMORY | USER MEMORY | TID MEMORY | Serial Number | TID Prefix | Access Password | Kill Password | Read sensitivity | Write sensitivity | Operating Temperatures |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alien Technology Higgs 4 | MICRO Heat | 128 bits | 128 bits | 64 bits | 32 bits | 32 bits | 32 bits | -20.5 dBm | -17 dBm | -50°C to +85°C | ||

| Alien Technology Higgs 9 | MICRO high temp, Slim TRAK | Large user memory | 96 bits | 688 bits | 48 bits | 32 bits | 32 bits | 32 bits | -20 dBm | -18 dBm | -50°C to +85°C | |

| Alien Technology Higgs 3 | PICO small, ROSWELL toughest, XS smallest | Large user memory | 96 bits | 512 bits | 64 bits | 32 bits | E200 3412 | 32 bits | 32 bits | -18.0 dBm | -13.5 dBm | -50°C to +85°C |

| NXP UCODE 9xm | Large user memory | 880 bits (flexible) | 880 bits (flexible) | 96 bits | 48 bits | 32 bits | 32 bits | -24 dBm | -22 dBm | -40°C to +85°C | ||

| NXP UCODE 9 | METAL SKIN printable labels | 96 bits | 0 | 96 bits | 48 bits | 32 bits | 32 bits | -24 dBm | -22 dBm | -40°C to +85°C | ||

| Impinj Monza M750 | MICRO Power, Cargo OUTDOOR, TRAK series, XPLATE series | 96 bits | 32 bits | 96 bits | 48 bits | E280 1190 | 32 bits | 32 bits | -24 dBm | -21 dBm | -40°C to +85°C | |

| Impinj Monza M781 | Large user memory | 128 bits | 512 bits | 96 bits | 48 bits | E280 11C1 | 32 bits | 32 bits | -23.5 dBm | -20.5 dBm | -40°C to +85°C | |

| Impinj Monza M780 | 496 bits | 128 bits | 96 bits | 48 bits | E280 11C0 | 32 bits | 32 bits | -23.5 dBm | -20.5 dBm | -40°C to +85°C | ||

| NXP UCODE 8 | PICO series | 128 bits | 0 | 96 bits | 48 bits | 32 bits | 32 bits | -23 dBm | -18 dBm | -40°C to +85°C | ||

| Impinj Monza R6-P | OUTDOOR series | 128 bits | 32 bits | 96 bits | 48 bits | E280 1170 | 32 bits | 32 bits | -22.1 dBm | -17.3 dBm | -40°C to +85°C | |

| Impinj Monza M4E | 96-496 bits | 128 bits | 96 bits | 48 bits | E280 110C | 32 bits | 32 bits | -19.5 dBm | -16.7 dBm | -40°C to +85°C | ||

| Impinj Monza M4QT | Large user memory | 128 bits | 512 bits | 96 bits | 48 bits | E280 1105 | 32 bits | 32 bits | -19.5 dBm | -16.7 dBm | -40°C to +85°C | |

| Quanray Qstar-56GN | MICRO X-II Automotive | Large user memory | 528 bits | 2 kbits | 256 bits | 32 bits | 32 bits | -19 dBm | -11 dBm | -40°C to +85°C | ||

| Axzon Magnus S3 | Passive temperature-sensing capabilities | 128 bits | 128 bits | 64 bits | 32 bits | 32 bits | -16.6 dBm | -9.9 dBm | -40°C to +125°C | |||

| Asygn AS3211.6 | XENSE sensors | Passive sensing capabilities | 192 bits | 96 bits | 48 bits | 32 bits | 32 bits | -13 dBm | -12dBm | -40°C to +125°C | ||

| Asygn AS3212.5 | Passive sensing capabilities | 192 bits | 32 bits | 48 bits | 32 bits | 32 bits | -13 dBm | -12dBm | -40°C to +120°C | |||

| Asygn AS3213.3 | Passive sensing capabilities | 192 bits | 32 bits | 48 bits | 32 bits | 32 bits | -13 dBm | -12dBm | -40°C to +120°C | |||

| Fujitsu MB97R8050-AP15-ES | XSKIN Gamma | Survives repeated Gamma ray irradiation | 160 bits | 0 | 176 bits | 32 bits | 32 bits | -12/20 dBm | -12 dBm | -40°C to +55°C | ||

| EM Microelectronic echo-V EM4425 | Dual frequency NFC+RFID, Large user memory | 480 bits | 512 bits | 96 bits | -20 dBm | -14.5 dBm | -40°C to +85°C |

FAQs RFID Chips

What is EPC Memory?

EPC (Electronic Product Code) memory is a specific type of memory found in RFID (Radio Frequency Identification) chips. It is used to store the unique identification number of an item or product. It can be updated or rewritten using the EPCglobal standard (aka encoded) by authorized users to reflect changes in the product or item.

The EPCglobal standard specifies a unique identifier for each item or product, which consists of three elements:

- Header: Specifies the type of EPC code being used.

- Unique Identifier (ID): A 96-bit number that uniquely identifies the item or product.

- Optional filter value: Can be used to group items or products based on certain criteria, such as the manufacturer or the product type.

EPC memory is separate from other types of memory on the RFID chip or tag, such as user memory or reserved memory. It is a non-volatile memory, meaning that it retains its data even when the chip or tag loses power. The amount of EPC memory available on an RFID chip or tag can vary, depending on the specific chip or tag and its intended application.

What is TID Memory?

TID is short for “Tag ID” and refers to the unique serial number assigned and written to the TID memory of a RFID chip by the manufacturer. The TID is made up of an unique identifier and may also contain other information such as the chip manufacturer’s information, the date and location of manufacturing, and the chip version number.

It cannot be modified or changed by the user. As such, it provides a unique identifier that allows RFID readers to distinguish one chip from another, even when multiple tags are present in the same field.

TID is important in RFID applications because it enables the reader to identify and differentiate between different types of RFID chips. For example, if a reader is designed to work only with a specific type of RFID chip, it can use the TID to verify that the correct chip is being used. In addition, TID can be used to track the origin and manufacturing history of the RFID chip.

TID prefix also plays a role in ensuring the security and privacy of RFID systems. By using unique TID prefixes, it is possible to prevent unauthorized access to the system and detect counterfeit or cloned RFID chips. This is especially important in applications where security and privacy are critical, such as in the healthcare, finance, and defense industries.

What is User Memory in an RFID chip?

User memory is a type of memory found in RFID (Radio Frequency Identification) chips and tags that can be used to store custom data or information specific to a particular application or use case. User memory is distinct from the other types of memory typically found in RFID chips, such as TID (Tag Identifier) memory and EPC (Electronic Product Code) memory, which are used for identification and tracking purposes.

User memory can be used to store a wide range of data or information, such as product specifications, maintenance records, or custom fields specific to a particular application or use case. This data can be read or written to the chip using specialized RFID readers and software applications.

The amount of user memory available on an RFID chip can vary depending on the specific chip or tag. Some chips may have only a small amount of user memory, while others may have several kilobytes or even megabytes of user memory available.

User memory can be useful in a variety of applications, such as asset tracking, inventory management, and supply chain management. By storing custom data or information specific to a particular application or use case, user memory can help to provide greater visibility and control over assets and inventory, and can facilitate more efficient and effective business processes.

In summary, user memory is a type of memory found in RFID chips and tags that can be used to store custom data or information specific to a particular application or use case. User memory is distinct from other types of memory typically found in RFID chips, such as TID memory and EPC memory, which are used for identification and tracking purposes. User memory can be useful in a variety of applications, such as asset tracking and inventory management, and can help to provide greater visibility and control over assets and inventory.

What is an RFID chip’s Reserved Memory?

The reserved memory stores an RFID chip data protection features: Two different security commands, “access” and “kill,” that allow users to control access to the data stored on a chip.

The “access” command is used to control read and write access to the data stored on the chip. It can be used to set up different levels of access for different users or applications, and can also be used to prevent unauthorized access to the data.

The “kill” command, on the other hand, is used to permanently disable the RFID chip or tag. It is typically used as a last resort to protect the data stored on the chip if it is lost or stolen. The “kill” command renders the chip or tag unusable, preventing anyone from accessing the data stored on it.

What is RFID read or write Sensitivity?

Read sensitivity is a measure of the ability of an RFID chip or tag to detect and respond to signals from an RFID reader. On the other hand, write sensitivity is a measure of the ability of an RFID chip or tag to receive and encode data from an RFID reader during the writing process.

A sensitivity value represents the minimum power level at which the chip or tag can reliably process the signal from the reader. It is measured in decibels per milliwatt (dBm) and is typically expressed as a negative value because it is a logarithmic measure of power ratios, with higher negative values indicating lower power levels and lower read sensitivity.

Read sensitivity and write sensitivity are important factors in RFID applications because they affect the reliability, range, and accuracy of the system. A more sensitive chip or tag can detect and respond to signals from a reader at longer distances, in noisy environments, or when there are obstructions or interference. On the other hand, a less sensitive chip or tag may require a stronger signal or a closer proximity to the reader to operate reliably, which can limit the range and efficiency of the system. A less sensitive chip might also be a preferred feature in a system as a solution for RFID collision prevention.

Sensitivity is determined by various factors, including the design and quality of the antenna, the power consumption, and the operating frequency. Different chips or tags may have different read sensitivities depending on their specifications and intended applications.

What are Operating Temperatures for RFID chips?

Operating temperatures refer to the range of temperatures within which an RFID chip can function properly, i.e. be read and written reliably.

RFID chips are sensitive to temperature and can be affected by extreme hot or cold temperatures. If an RFID chip is exposed to temperatures outside of its specified operating range, it may not function properly and need to wait for temperatures to be within ranges.

In applications where RFID is used in harsh environments, such as industrial settings or outdoor environments, this usually involves selecting specialized tags (e.g. high- temperature tags) and designing the workflow around temperature cycling

It is important to select chips and tags that are designed to withstand the specific operating temperatures and environmental conditions of the application.